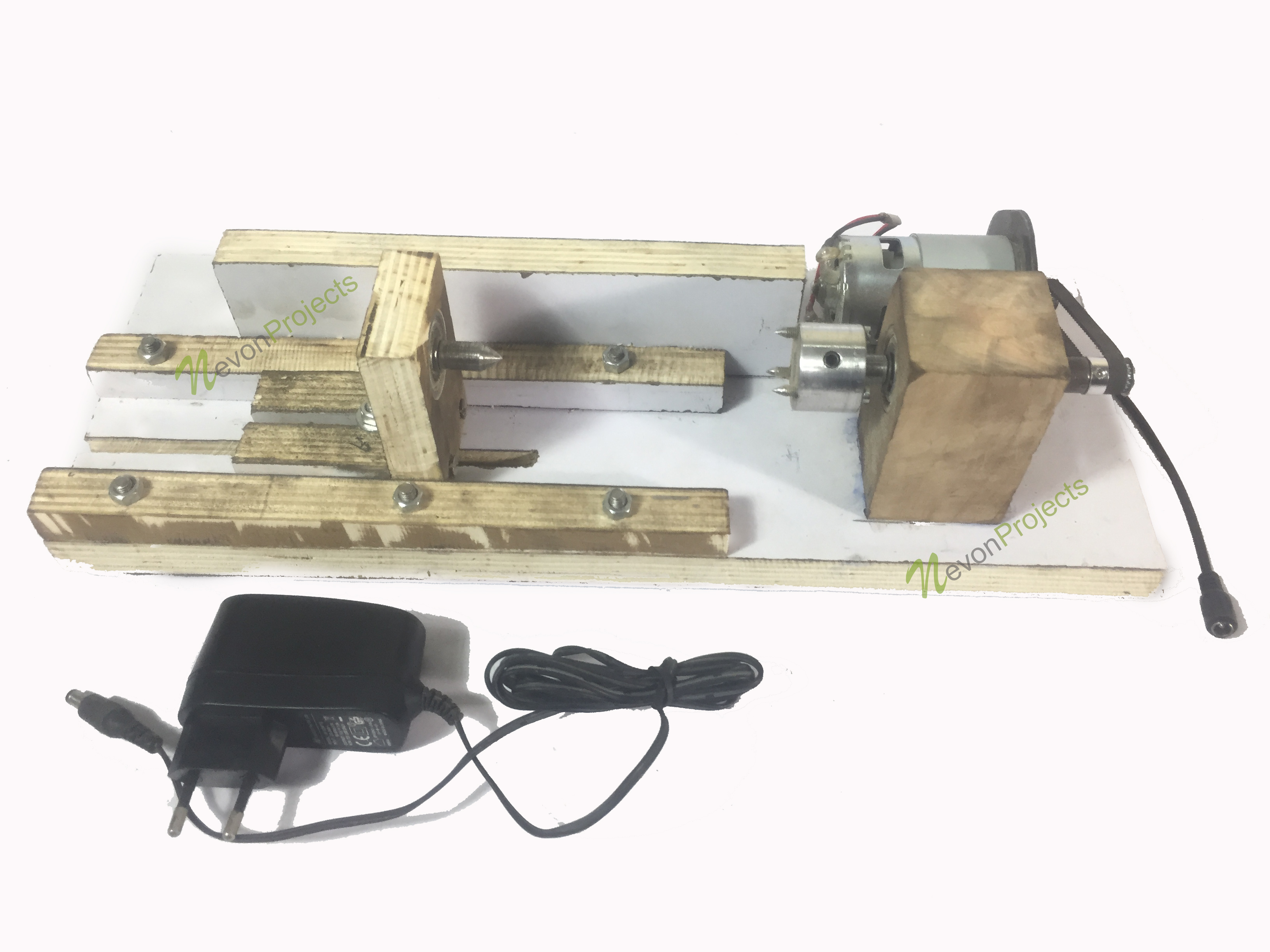

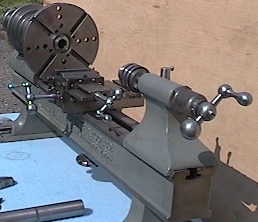

Of course, the carriage is not calibrated so you get to practice your guessing skills. I must place my left hand thumb on the carriage pushing back while driving the carriage forward with my right hand. An example, On my 7X16 Chinese Mini Lathe, attempting to control the carriage position is a two hand job. To further state this, if you must develop skills to manipulate your lathe to do what it is suppose to do, then it is unlikely you will be happy with the result. Another words, what comes off of your lathe will be determined by your ability to control the the lathe tool. (3) While spindle accuracy is important, it is useless unless you have a way of accurately controlling the lathe tool (Carriage and cross slide). I would suggest Collet options that include WW because of the readily available collet options as well as machinable jaws for chucks and pot collets. (2) You will need a wide range of work holding options that should include properly scaled 3 jaw, 4jaw chucks both self centering and independent for holding clock size parts. Often, high torque claims only means a few seconds and is not consistent at any speed. Do not be taken in by advertising claims. (1) In todays world, most Lathe spindles including the Chinese lathes are accurate enough for Clock work, however consistent high torque variable speed drive is a must on small Lathes. I would first suggest you consider and research the following. If your not that serious, just about anything will do.Īssuming that you are serious, then the differences between Lathes can not be explained but must be experienced. One must first determine how serious you are about your work. I am seeing people offer ER-8 and ER-11 collet adapters for some of these products which might well assist in the need for small collets for clock work. It does have drawbacks, several of which have been resolved in their more recent versions of these machines. That said, I have one of their mills and have been quite pleased with it overall.

The machines are quite robust, not as smooth in finish or in tolerances as perhaps a Sherline, but they have a larger capacity, they have a much greater mass, and they are able to hold tolerances suitable for clock work. They seem to stock the best array of parts and accessories for these machines and I share their site only to provide information for this thread. You might try checking out "littlemachineshop dot com to see what accessories can be had for these machines. They also suffer from some of the same issues of the Unimat.namely tight work spaces around the tool post and cross slides, other issues like a lack of common collets I often find needed for the work I do, and a general lack of accessories for clock work. Personally speaking I find them too small to be entirely useful for clocks.

0 kommentar(er)

0 kommentar(er)